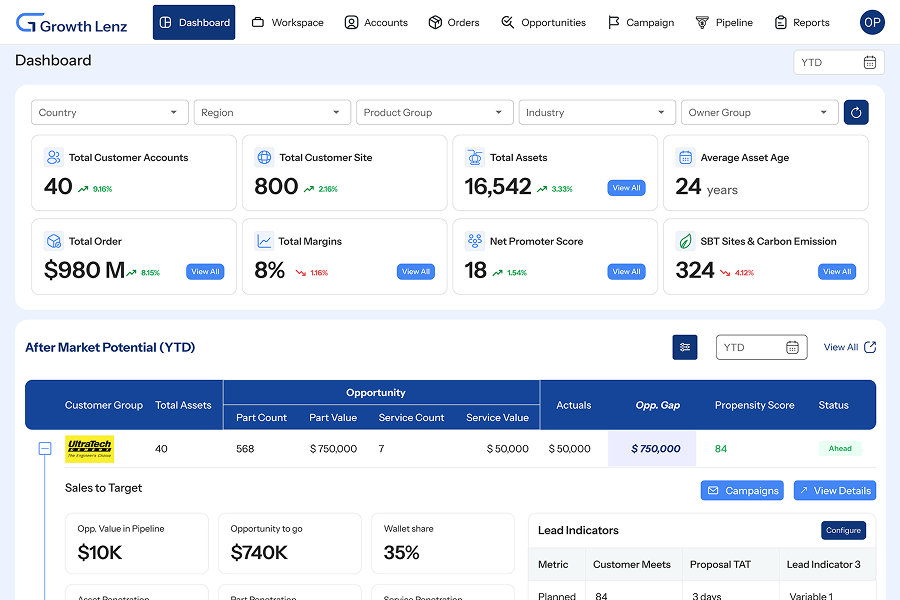

Asset Lifecycle Management in manufacturing is not just about tracking — it’s about extracting maximum performance, reducing lifecycle costs, and driving operational excellence. GrowthLenz delivers advanced asset lifecycle management solutions that enable complete inventorisation of assets, sub-assets, parts, and sub-parts through structured ontology and taxonomy frameworks. Our intelligent asset lifecycle management software enables full lifecycle visibility, establishes equipment hierarchies, and triggers proactive maintenance actions based on operational thresholds, usage patterns, and criticality. It also incorporates IoT-powered real-time asset health monitoring, warranty tracking, and proactive parts replacement to avoid unplanned downtime and extend asset life.

Built on proven asset lifecycle management best practices, our platform helps manufacturers improve uptime, optimize spare part planning, reduce maintenance costs, and drive tangible ROI — all through a connected, performance-driven approach.

Within the product domain,

there are:

Asset Lifecycle Management typically includes the following key stages:

Each stage is supported by data and digital workflows to ensure lifecycle visibility, cost control, and performance optimization.

Key Performance Indicators (KPIs) used to measure the effectiveness of asset lifecycle management software include:

These KPIs help organizations evaluate maintenance efficiency, asset performance, and return on asset investment.