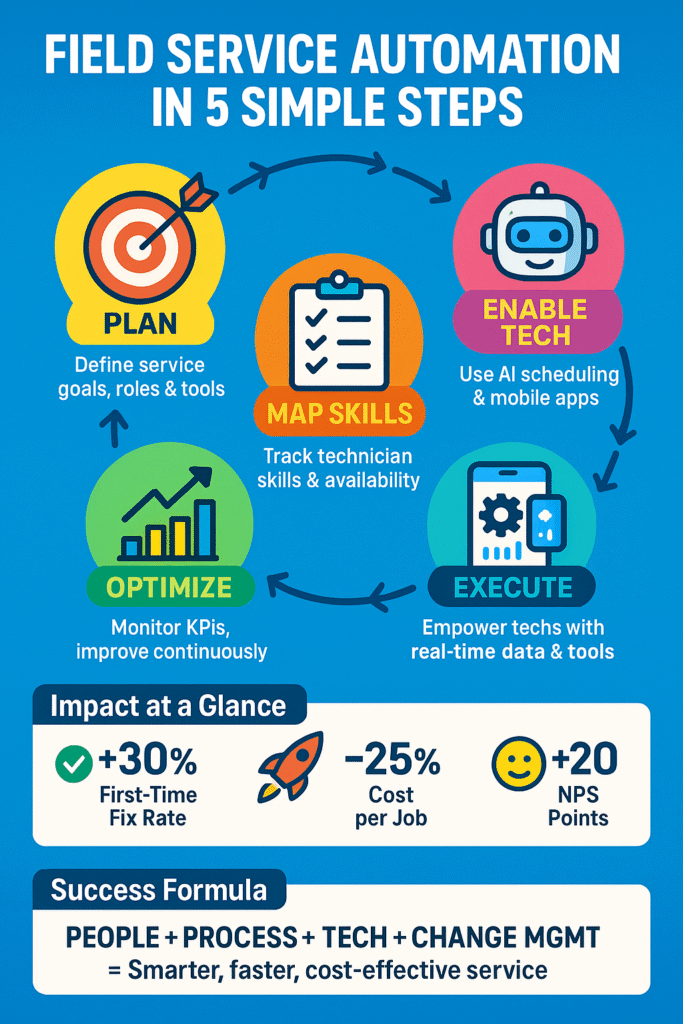

Deployment typically involves a multi-phase approach with technology, process, and people components working in sync.

Phase 1: Strategy & Planning

Key Activities:

- Define field service goals – What does the organization aim to achieve? (e.g., reduce service time, increase first-time fix rate, lower cost-to-serve)

- Define all field service roles – Who does what? (Include service managers, field technicians, service coordinators, etc.)

- Assess current systems – What systems are used by the service teams? (ERP, CRM, EAM, manual scheduling tools)

- Build service taxonomy – Is proper skill assessment done across the workforce? (Documented skill matrix, standardized levels, certifications, asset types, regions, etc.)

Outcome:

A clear roadmap aligned with business KPIs and service-level goals.

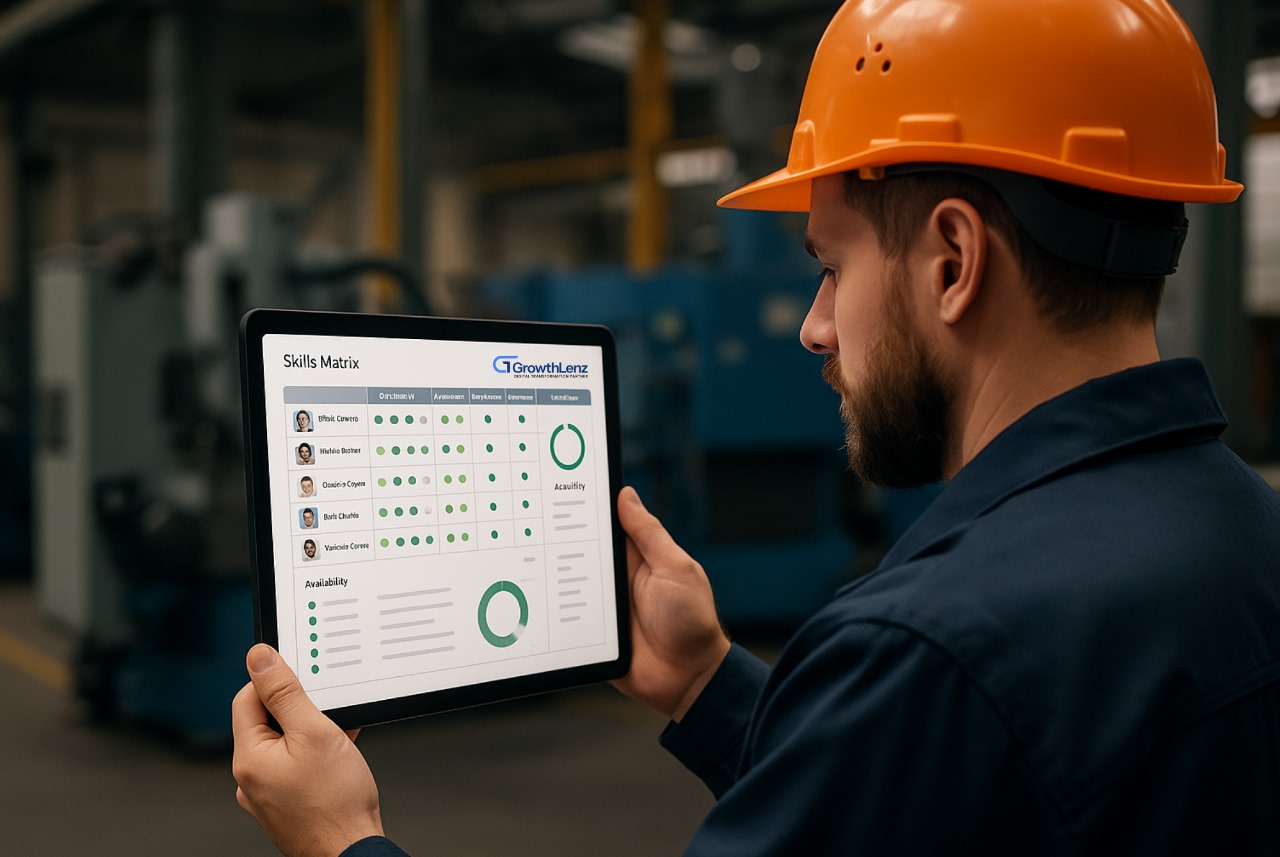

Phase 2: Map Competency & Availability

Key Activities:

- Create a technician competency matrix (skills, certifications, training records) using the Skill Ops platform

- Integrate with HR/learning systems for real-time skill data updates

- Capture technician availability including shift schedules, time-off, and location

Outcome:

A dynamic technician profile database that supports intelligent dispatching.

Phase 3: Technology Enablement

Platform Components:

- Field Service Management Platform using Sync 360 Expert

- Scheduling Engine with AI/ML: Automates dispatch based on location, skill, availability, workload

- Mobile Field Technician App: Real-time job details, digital checklists, asset history, manuals, knowledge base

- Customer Portal (optional): For service request creation, technician tracking, and feedback submission

Integrations:

- ERP/CRM platforms to manage customer information, warranty details, and order history

- Asset Management for installed base details and asset health

- Knowledge Management for guided on-site troubleshooting

Outcome:

An integrated field service ecosystem that automates scheduling, dispatch, and execution.

Phase 4: Field Execution & Mobility

Key Activities:

- Equip field teams with mobile apps or tablets

- Offer access on demand to:

- Work orders and job location

- Asset service history

- Digital service manuals and troubleshooting guides

- Spare parts availability and ordering

- Real-time collaboration or remote support via video/AR

Outcome:

Technicians are self-sufficient, more productive, and capable of delivering a better service experience.

Phase 5: Monitoring & Optimization

Key Activities:

- Track key performance indicators (first-time fix rate, technician efficiency, travel duration, response speed)

- Apply dynamic dashboards and analytics to fine-tune dispatch strategies

- Gather insights from technicians and customers to drive ongoing improvements

Outcome:

Consistent gains in service quality, workforce effectiveness, and customer satisfaction.

Key Success Factors

| Area | Key Enablers |

| People | Competency-based workforce planning, continuous training |

| Process | Standardized workflows, digital SOPs, escalation paths |

| Technology | Robust FSM platform, AI scheduling, mobile enablement, integrations |

| Change Management | Technician buy-in, stakeholder alignment, leadership sponsorship |

Quantifiable Business Benefits

| Metric | Typical Improvement |

| Technician productivity | +25–35% |

| First-time fix rate | +20–30% |

| Service cost per job | −15–25% |

| Downtime reduction | −20–30% |

| Customer satisfaction (NPS) | +10–20 points |

| Response time | −30–40% |

Use Case Example: OEM Deployed FSA for Aftermarket Service

A global industrial equipment OEM implemented FSA to manage 600+ service technicians across 12 countries. By automating technician dispatch based on skill, location, and availability, and integrating with their ERP and IoT platforms:

- First-time fix rate improved from 62% to 82%

- Average response time dropped by 38%

- Aftermarket service revenue grew by 18% YoY

- Customer satisfaction rose by 22 points (NPS)

Conclusion

Field Service Automation empowers manufacturers and OEMs to move from manual, reactive service to automated, predictive, and customer-centric field operations.

By intelligently matching technician competency and availability to job requirements, organizations can:

- Speed up service execution and improve operational efficiency

- Cut expenses and prevent unplanned equipment breakdowns

- Increase aftermarket margins and drive recurring revenue

In today’s digital era, field service has evolved from a support role to a key competitive advantage.

Are you still relying on manual service coordination?It’s time to shift to a smarter, automated field service model. Let’s talk about how we can optimize your service operations—drop a message or connect now.