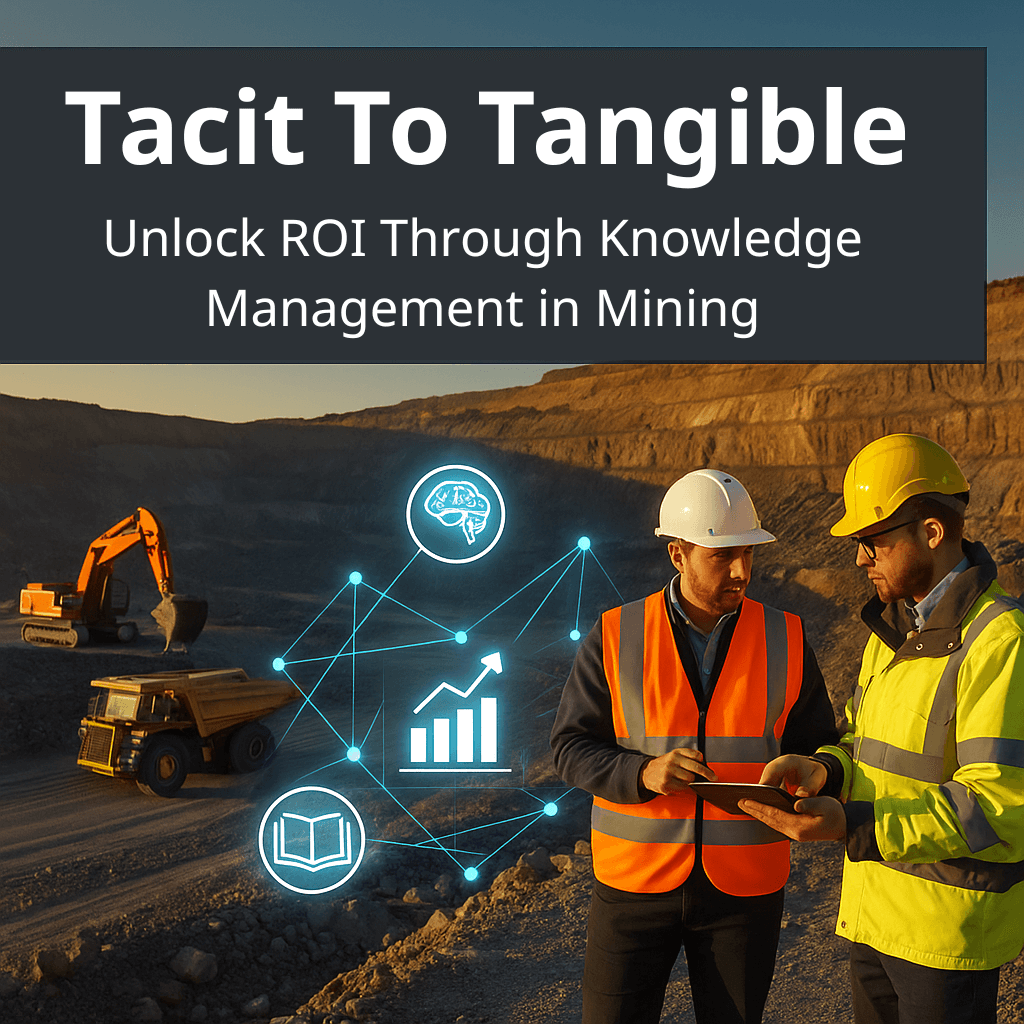

In the mining industry, critical know-how often lives in the minds of veteran operators, engineers, and foremen — quietly powering daily operations. But when this experience isn’t documented, it becomes a liability. Retirements, attrition, or transfers can mean vital knowledge walks out the door.

The solution? A smart, structured Knowledge Management System (KMS) that transforms tribal expertise into reusable, accessible assets — reducing resolution time, improving consistency, and ensuring business continuity.

The Hidden Bottleneck in Mining

Let’s be direct — mining is high-stakes and complex:

- Remote-site equipment failures

- Tight environmental and regulatory compliance

- High-risk activities with rising cost pressure

Despite this, many operations still rely on outdated knowledge-sharing methods: fragmented emails, aging PDFs, and isolated spreadsheets. This slows onboarding, leads to recurring errors, and delays decisions — all of which impact uptime, safety, and profitability.

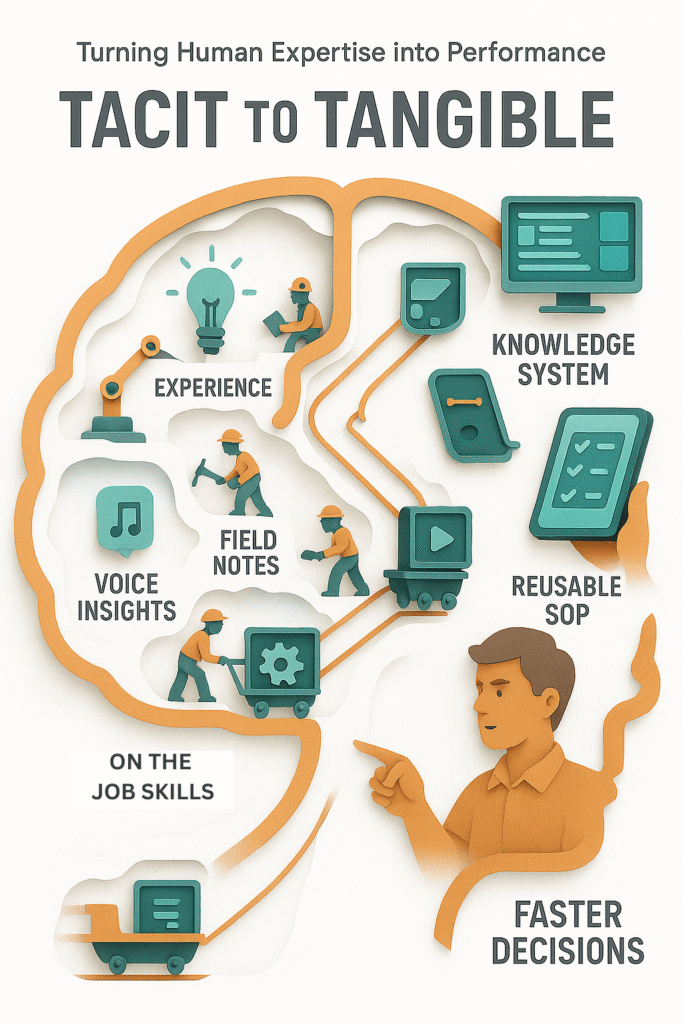

Tacit to Explicit: The Real ROI Driver

Tacit knowledge — deeply personal and experience-based — is often difficult to articulate. But once captured in a digital KMS, it becomes searchable, scalable, and strategically valuable.

Real-World Example:

A seasoned geologist’s method for spotting early signs of slope instability was captured as a training module in the KMS. The result? Young engineers across multiple sites now act days earlier, preventing costly downtime and reducing risk of injury.

ROI That Speaks Volumes

Mining organizations that adopt structured knowledge systems report measurable benefits:

- 20–30% faster issue resolution

- 40% reduction in repeat problems

- 30–50% faster onboarding of new staff

- 15% improvement in Overall Equipment Effectiveness (OEE)

- Significant cost savings by reducing dependence on external contractors

Don’t Reinvent the Wheel. Repurpose It.

Every shutdown repair, inspection, and field report contains valuable lessons. But without a system to capture and contextualize this, teams end up reinventing the wheel — again and again.

A modern KMS enables:

- Evolving and sharing SOPs across teams

- Leveraging historical data for predictive maintenance

- Rapid access to lessons during audits or crisis response

How to Get Started: The Fast Path to Value

Here’s how mining organizations can begin turning expertise into structured intelligence:

- Pinpoint high-impact domains – Maintenance, safety, geology, environment

- Capture expert knowledge – Use video walkthroughs, voice-to-text journals, and annotated field notes

- Structure it smartly – Move beyond folders. Use tags, metadata, and workflows

- Embed in the workflow – Ensure offline/mobile access, multi-language options, and contextual prompts

- Track and evolve – Monitor usage and improve based on feedback

Final Word: Institutionalize Expertise Before It Walks Out the Gate

Mining is capital-intensive, data-rich, and operationally diverse. But success increasingly hinges on how fast organizations can transfer knowledge — from seasoned professionals to new hires, from one site to another, from problem to resolution.

By building a KMS that spans tacit and explicit knowledge, you convert human capital into performance capital — and turn experience into a repeatable competitive edge.

At GrowthLenz, we help mining and heavy industries build practical, intelligent KMS frameworks tailored for real-world environments. Because performance shouldn’t be dependent on who’s on shift.

Interested in exploring this in your context? Let’s co-design a pilot in your operations.

Contact us: https://growthlenz.com/contact-us/

#KnowledgeManagement #MiningIndustry #OperationalExcellence #DigitalTransformation #KMS #GrowthLenz #AssetHeavyIndustries