In the cement industry, efficiency conversations often revolve around major assets like kilns, crushers, mills, and conveyors. Yet, the silent drivers of uptime and performance often sit quietly in the inventory racks: spares and consumables.

Sometimes it’s not the million-dollar kiln that stops production; it’s $50 parts that no one noticed.

From a worn-out bearing in a raw mill to a critical gearbox seal on the packing line, the smallest overlooked component can bring a multi-million-dollar plant to a standstill.

The Hidden Impact of Spare Parts Strategy

A typical 1 MTPA cement plant may operate with over 5,000 SKUs of spare parts and consumables, ranging from conveyor belts to lubrication oil. Poor management of these items can lead to:

- Unplanned Downtime: A single hour of lost production can cost $10,000–$15,000 in lost output.

- Overstocking Costs: Carrying excess inventory ties up 15–20% of working capital.

- Procurement Delays: Lead times for imported spares can stretch to 8–12 weeks, creating high-risk vulnerability if demand isn’t forecasted.

In short, your spare parts strategy is not just a maintenance function — it’s a profit and risk management lever.

Why Spares & Consumables Drive Performance

Predictability of Maintenance

Plants with digitized spare parts planning experience 30–40% fewer emergency breakdowns, enabling proactive servicing.

Faster Mean Time to Repair (MTTR)

When spares are readily available, repair times can be reduced by 50–60%, minimizing lost production hours.

Lower Total Cost of Ownership (TCO)

Well-managed consumables reduce wear on high-value equipment, extending operating life by 12–18 months.

Optimized Working Capital

Using ABC-XYZ analysis and consumption-based forecasting, plants can cut spare inventory value by 15–25% without increasing stock-out risk.

Key Metrics to Track

| Metric | Why It Matters | Benchmark |

|---|---|---|

| Stock-Out Rate | Measures unavailability of required parts | < 2% |

| Inventory Turnover Ratio | Efficiency of inventory use | 2–4 turns/year |

| MTTR | Direct link to downtime impact | Reduce by 50% from baseline |

| Critical Spares Coverage Days | Readiness for high-impact failures | ≥ 90 days |

| Capital Tied in Inventory (%) | Working capital efficiency | 12–15% of annual OPEX |

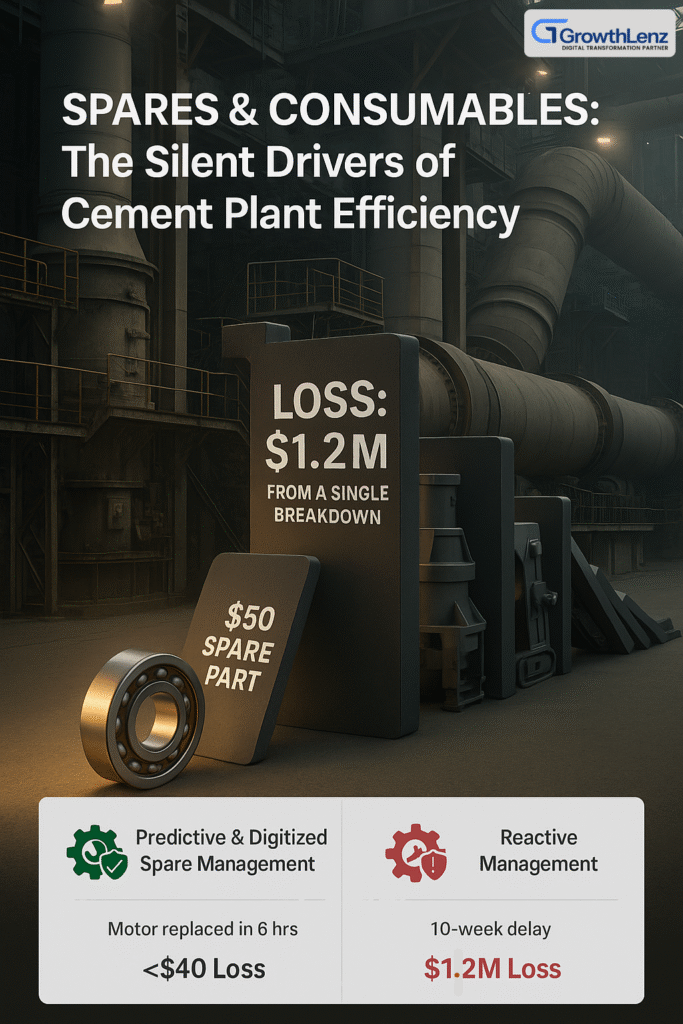

Benchmark Scenario: The Difference Strategy Makes

Scenario A: Reactive Spare Parts Management

A cement plant waits for breakdowns before checking availability. A packing line motor fails unexpectedly; lead time for a replacement is 10 weeks. Production loss: $1.2 million.

Scenario B: Predictive & Digitized Spare Parts Management

The same plant tracks part health and stocks critical spares based on failure risk. The same motor fails but is replaced within 6 hours. Production loss: less than $40,000.

The difference? $1+ million saved — simply by having the right part at the right time.

Action Plan for Cement Plants

- Digital Inventorisation – Map every spare part with a unique ID, equipment linkage, and consumption history.

- Consumption-Based Forecasting – Use 12–24 months of consumption data to accurately forecast future needs.

- Criticality Classification – Prioritize stocking based on failure impact and lead time.

- Vendor Partnerships – Secure long-term agreements for critical parts with guaranteed lead times.

- Integration with Maintenance Planning – Synchronize spare parts data with preventive and predictive schedules.

The Bottom Line

In high-capacity cement plants, uptime is profit — and uptime is built not just on big-ticket machinery, but on the smallest components that keep them running.

A strategic, data-driven approach to spares and consumables can deliver:

- 20–25% reduction in maintenance costs

- 30–40% increase in equipment availability

- 15–25% improvement in working capital utilization

Managing your spares isn’t about counting nuts and bolts — it’s about unlocking hidden capacity and protecting your plant’s bottom line.

GrowthLenz helps industrial leaders move from reactive to predictive asset management — ensuring every spare part in your inventory works as hard as your equipment does.