Introduction

As sustainability transitions from corporate buzzword to boardroom discussions, manufacturers are seeking practical ways to align operations with environmental, social, and governance (ESG) goals. One overlooked yet highly impactful area is maintenance. As we know, maintenance costs usually account for 30–60% of the operating expenditure (Opex), making this an area of strategic importance.

Traditional maintenance often follows fixed schedules rather than actual asset condition. This leads to:

- Over-maintenance: wasting labor and parts,

The result? Cost-optimal maintenance frequency is rarely achieved.

As an alternative to preventive maintenance many manufacturing units have adopted condition-based monitoring using IoT sensors, thereby capturing the real time status of the equipment condition and maintenance requirements. However there are two major challenges to using Condition monitoring – it is cost prohibitive and usually not implementable for legacy equipments.

So, what’s the middle path manufacturing companies should follow?

As the proverb goes, “A journey of a thousand miles begins with a single step.” In manufacturing, operational excellence is not achieved overnight—it’s built through incremental improvements and consistent execution. One of the most impactful steps manufacturers can take is optimizing how they maintain their fixed assets. For organizations with distributed assets, increasing efficiency and labor productivity hinges on optimizing preventive maintenance.

The Missing Link: Middle path between Preventive and Predictive Maintenance

The core challenge in maintenance optimization is simple yet powerful:

“How do we know when an asset actually needs maintenance?”

The answer lies in comparing:

- Design Requirements (OEM specs and intended use),

- Historical Performance Data (actual usage, failure patterns, wear rates) using FMEA data.

This comparison enables:

- Prioritized and accurate maintenance scheduling,

- Reduction in unexpected breakdowns,

- Improved asset lifecycle,

- Lower maintenance cost per unit of output.

By integrating this approach with digital tools which are simple and scalable, manufacturers can shift from reactive or time-based maintenance to optimized preventive maintenance strategies.

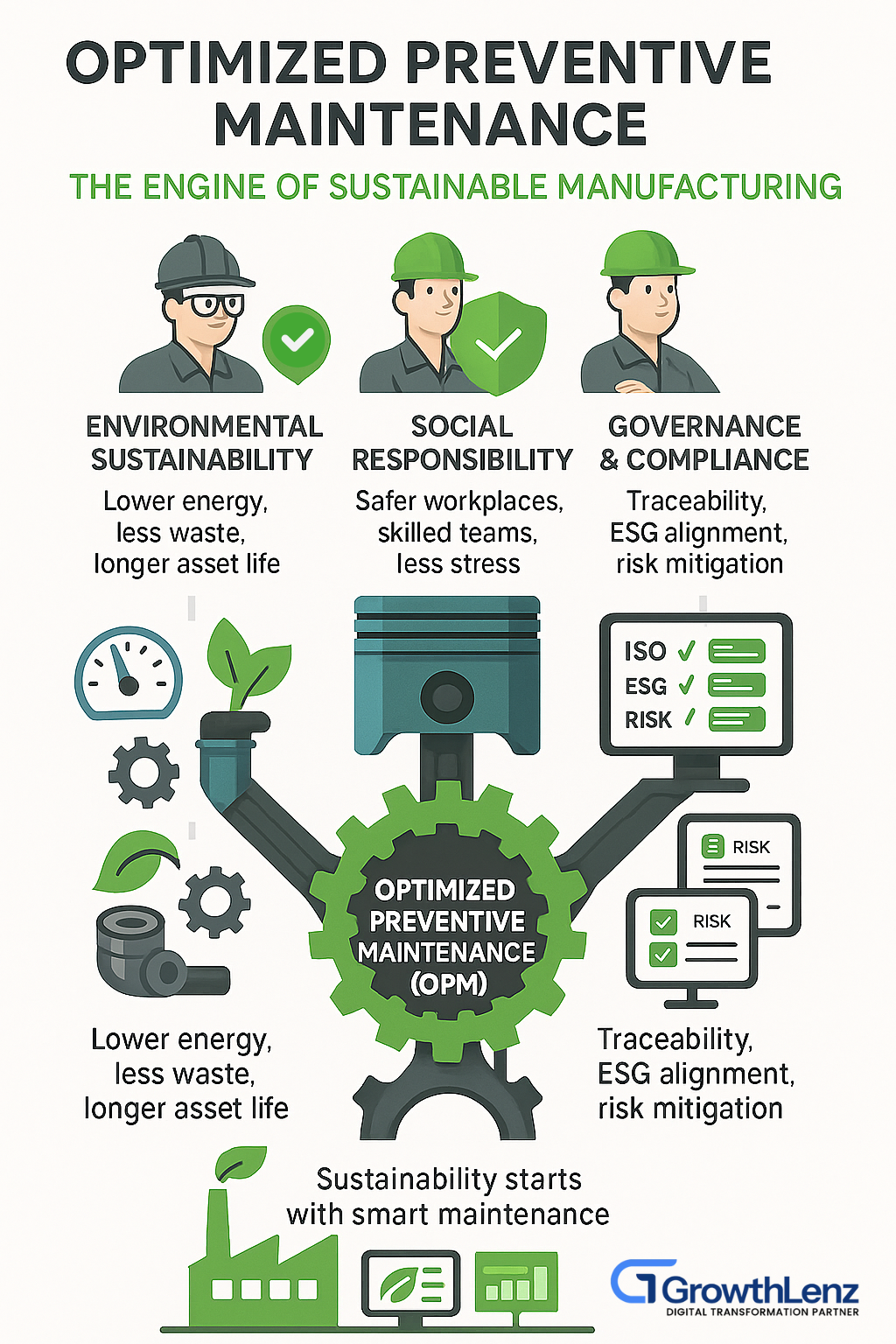

Optimized Preventive Maintenance (OPM) is not just a strategy for operational efficiency and cost savings; it’s a foundational element in any sustainability-driven manufacturing approach.

We explore how OPM contributes to sustainability across three key dimensions: environmental impact, social responsibility, and governance excellence.

Environmental Sustainability: Reducing Waste, Emissions, and Energy Use

- Lower Energy Consumption

Inefficient, poorly maintained equipment often consumes more energy. OPM ensures machines operate at peak performance, reducing unnecessary energy use and lowering carbon emissions. - Prolonged Asset Life

Through condition-based servicing and intelligent scheduling, assets last longer. This reduces the frequency of equipment replacement, cutting down on raw material extraction, manufacturing emissions, and end-of-life waste. - Fewer Breakdowns, Less Environmental Risk

Unplanned failures can lead to hazardous emissions or spills. Preventive maintenance reduces the likelihood of such events, ensuring equipment operates within safe environmental parameters. - Smarter Resource Use

Avoiding both over- and under-maintenance minimizes unnecessary use of parts, lubricants, and consumables, reducing manufacturing’s material footprint.

- Lower Energy Consumption

Social Responsibility: Safer, Smarter, and More Sustainable Workplaces

- Improved Safety

Regular and condition-based maintenance lowers the risk of accidents due to equipment failure. This contributes to a safer work environment and boosts employee morale. - Upskilling the Workforce

Digital tools used in OPM empower technicians to interpret data, use diagnostics, and make real-time decisions—leading to a more skilled and future-ready workforce. - Reduced Field Stress

By minimizing emergency repairs and travel, OPM promotes a healthier work-life balance for field teams, reducing fatigue and stress.

- Improved Safety

Governance and Compliance: Enabling Transparency and Risk Mitigation

- Enhanced Traceability

Digital maintenance records support audits and compliance with global standards like ISO 14001 (Environmental) and ISO 55001 (Asset Management), providing traceable and verifiable data. - Proactive Risk Management

Regular maintenance reduces the risk of large-scale operational or environmental incidents, helping companies avoid regulatory fines and reputational damage. - ESG Reporting Alignment

Metrics such as reduced downtime, extended asset life, energy savings, and fewer incidents feed directly into ESG disclosures, demonstrating tangible sustainability progress.

- Enhanced Traceability

Supporting the Circular Economy

- Optimised maintenance contributes to circular manufacturing practices by:

- Enabling asset refurbishing through historical performance data,

- Identifying components for reuse or recycling,

- Making data-driven decisions on when to repair, repurpose, or retire assets.

- Optimised maintenance contributes to circular manufacturing practices by:

Conclusion: Sustainability Starts with Smart Maintenance

Optimized Preventive Maintenance delivers measurable value not only in efficiency and cost reduction but also in advancing sustainability goals. By reducing waste, improving safety, enabling transparency, and supporting the circular economy, OPM becomes a crucial lever in a manufacturer’s ESG strategy.

In the journey toward sustainable industry practices, smart maintenance isn’t just part of the solution—it’s a strategic starting point.

Don’t just maintain—optimize. Let’s build a smarter, greener future together. Contact us: https://growthlenz.com/contact-us/