Introduction

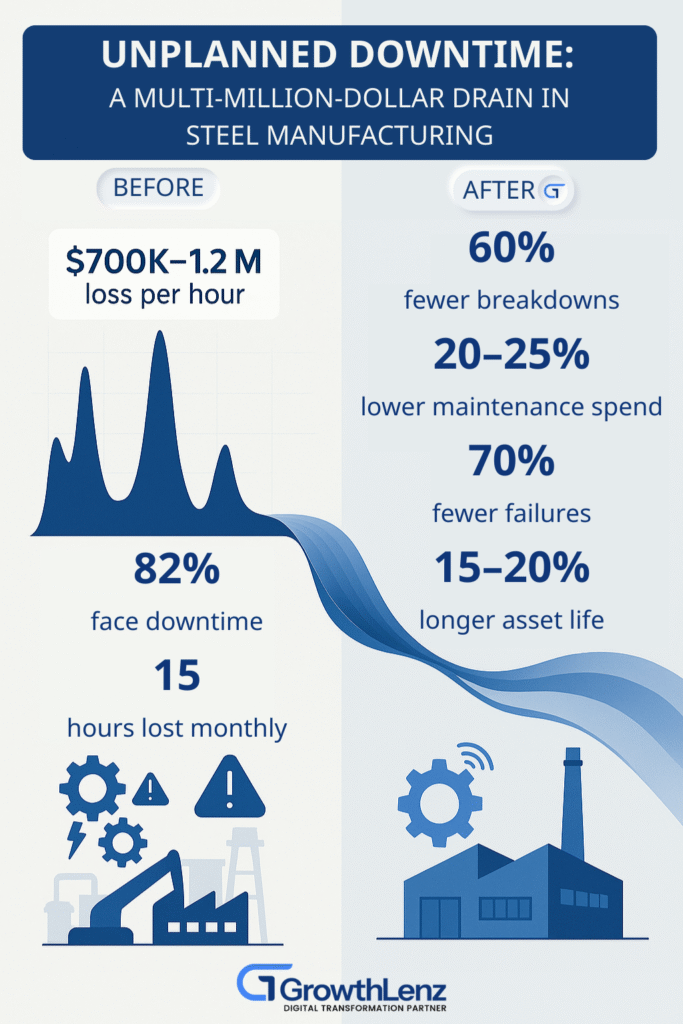

In the steel industry, downtime is not just an operational inconvenience: it is a direct hit to profitability. Global benchmarks estimate that unplanned downtime costs manufacturers nearly USD 50 billion annually, with some steel plants losing over USD 1 million per hour when critical equipment fails.

This article highlights how predictive asset intelligence can prevent such losses, drawing from benchmark cases and real-world transformations.

The Hidden Cost of Downtime

For a typical integrated steel plant, one unplanned stoppage in a blast furnace or continuous casting unit can trigger:

- Loss of USD 700,000–1,200,000 per hour in direct production.

- Ripple effects across supply chains, causing missed delivery commitments.

- Safety risks, as emergency repairs bypass standard maintenance procedures.

A McKinsey study revealed that 82% of manufacturing companies experience unplanned downtime each year, averaging 15 hours of lost production per month. For a steel major, that is equivalent to tens of millions in lost revenue annually.

Benchmark Insights: What Industry Leaders Achieved

Several leading players in asset-heavy industries have shown how predictive maintenance can drive measurable results:

- A global metals producer achieved a 25% reduction in maintenance costs by deploying real-time monitoring across furnaces and rolling mills.

- A mining company avoided USD 34 million in annual losses through predictive maintenance of haul trucks and conveyors.

- A cement manufacturer cut downtime by 30%, extending the lifecycle of rotary kilns and reducing emergency spares costs.

The steel industry, with its continuous operations and high capital intensity, stands to gain even more.

The Shift to Predictive Asset Intelligence

The breakthrough comes from using IoT-enabled sensors, AI-driven anomaly detection, and integrated maintenance platforms. Instead of reacting to failures, plant teams can:

- Detect anomalies weeks in advance.

- Schedule planned interventions during low-load periods.

- Optimize spare parts inventory based on real usage patterns.

- Strengthen compliance with digital audit trails.

This transformation ensures that downtime, while inevitable, no longer derails production or profitability.

The Results: Business at Scale

Steel manufacturers adopting predictive intelligence typically see:

- Up to 60% reduction in unplanned breakdowns

- 20–25% lower maintenance spend

- 70% fewer critical equipment failures

- Extended asset lifecycles by 15–20%

For a mid-to-large steel plant, this translates into multi-million-dollar savings annually, improved supply chain reliability, and a stronger competitive edge.

Conclusion

In steel manufacturing, uptime is money. Benchmarks clearly show that companies investing in predictive intelligence are not just avoiding downtime: they are securing profitability, compliance, and long-term resilience.

At GrowthLenz, we partner with manufacturers to bring these outcomes to life, transforming downtime risk into measurable value.

The lesson is clear: don’t let unplanned downtime decide your margins.

Connect with us to explore how predictive asset intelligence can safeguard your operations.

https://growthlenz.com/contact-us/